What is Carbon Fiber Reinforced Concrete?

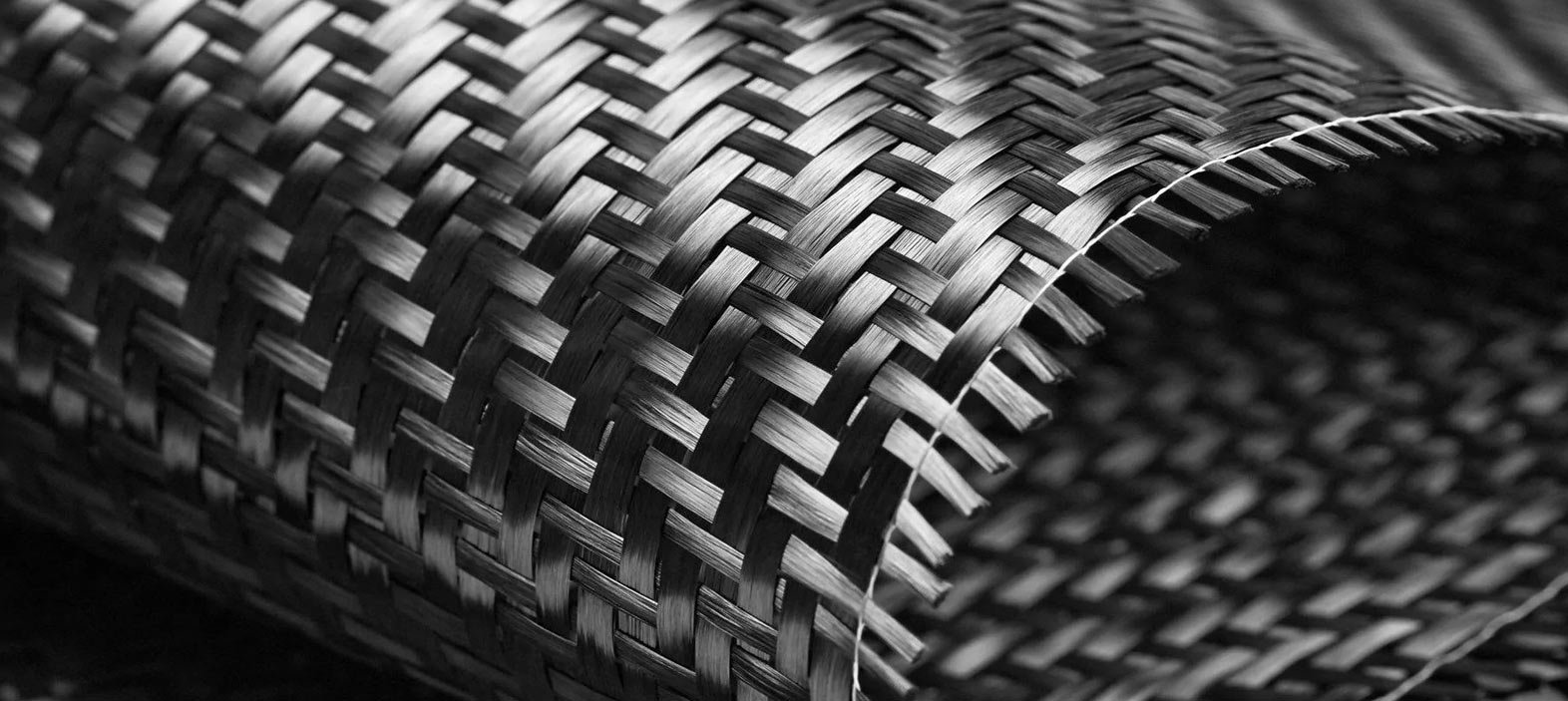

Carbon Fiber Reinforced Concrete (CFRC) is an advanced composite material that incorporates carbon fiber to enhance the properties of traditional concrete. By integrating carbon fiber strands into the concrete mix, the material gains significantly improved strength, durability, and crack resistance, making it suitable for demanding applications where high-performance materials are required.

Benefits of Carbon Fiber Reinforced Concrete

Carbon fiber reinforcement offers several advantages over conventional reinforcement materials such as steel. Some of the key benefits include:

- Enhanced Durability: Carbon fibers are resistant to corrosion, unlike steel reinforcement, which can rust over time when exposed to moisture and harsh environments.

- Increased Strength-to-Weight Ratio: The addition of carbon fibers strengthens the concrete without adding significant weight, making it an ideal choice for projects that require lightweight yet durable materials.

- Crack Resistance: The fibers help prevent the propagation of cracks, increasing the longevity and stability of concrete structures.

- Reduced Maintenance Costs: Due to its corrosion resistance, CFRC requires less maintenance compared to traditional reinforced concrete, leading to long-term cost savings.

- Improved Flexural Strength: The carbon fibers enhance the concrete’s ability to resist bending and flexing forces, making it ideal for areas subject to dynamic loading conditions.

Applications of Carbon Fiber Reinforced Concrete

The versatility of CFRC makes it suitable for a variety of applications, particularly in environments that are prone to corrosion or extreme stresses. Some common uses include:

- Bridge Construction: CFRC is used in bridge decks and support structures to increase the lifespan and reduce the need for frequent repairs.

- Marine Structures: It is ideal for structures exposed to seawater, as the carbon fiber’s resistance to corrosion can significantly extend the life of concrete in harsh marine environments.

- Highway Pavements: For roads and pavements subjected to heavy traffic and extreme weather conditions, CFRC offers improved resistance to wear and tear.

- Reinforcement of Existing Structures: CFRC can be used for retrofitting and strengthening old buildings or bridges, especially when traditional materials may not provide sufficient performance.

Advantages Over Traditional Reinforcement

When compared to traditional steel reinforcement, carbon fiber offers several distinct advantages:

- Corrosion Resistance: Unlike steel, carbon fibers do not corrode when exposed to moisture, chemicals, or salts, making them particularly suitable for coastal or industrial environments.

- Lightweight: Carbon fiber reinforcement is much lighter than steel, which can reduce the overall weight of the structure, making it easier to handle and transport.

- Better Performance in Extreme Conditions: Carbon fibers can withstand higher temperatures and aggressive environments without losing their strength, unlike steel which can weaken in certain conditions.

Conclusion

Carbon Fiber Reinforced Concrete is an innovative and highly efficient material that enhances the strength, durability, and performance of concrete structures. Whether used in new construction or retrofitting existing buildings, CFRC offers long-lasting benefits, reduced maintenance costs, and increased resistance to environmental challenges. As the demand for high-performance, sustainable materials continues to grow, CFRC stands as a promising solution for modern construction projects.